Steel Conduit Pipe Systems

STEEL CONDUIT PIPE SYSTEMS.

We have 3 types of conduit systems ; Threadless conduit systems, Thickwall conduit systems, Rigid steel conduit systems.

We assure that our conduit systems are easy to bend, to cut, and to join.

They are made from Aluminium, Steel, Stainless Steel, Hot dipped galvanization.

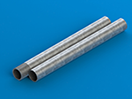

THREADLESS STEEL CONDUIT SYSTEMS

This type is galvanized on exterior with a special lubricating coating applied to the interior to permit easier wire pulling. It can be used for both exposed and concealed work providing it will not be subject to severe physical damage and is property protected against corrosion. It is most commonly used above ground for lighting circuits, control line and other low power applications.

Newly development in galvanizing process for protection against atmospheric corrosion and exterior erosion which is finished with heavy duty galvanized protection both inside and outside the conduit pipe (Class 4 - Heavy protection both inside and outside - refer to BS 4568 : part 1 : 1970).

Features:

1. High Quality Conduit,

2. High Quality Galvanization,

3. Heavy Duty Galvanized Protection - Class 4,

4. Easy Wire Pushing and Pulling,

5. Modern Process & High Quality Material,

6. International Quality Management System,

7. International Health and Safety Management System,

8. International Product Certification,

|

|

|

| Steel Pipe Conduit |

Steel Pipe Conduit |

Steel Pipe Conduit |

|

|

|

| Steel Pipe Conduit |

Steel Pipe Conduit |

Steel Pipe Conduit |

|

|

|

| Steel Pipe Conduit |

Steel Pipe Conduit |

Steel Pipe Conduit |

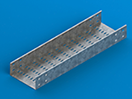

THICKWALL STEEL CONDUIT SYSTEMS

Thickwall conduit systems is made from high strength flat steel that is cold formed and electrically welded in a uniformly tube. This conduit is capable of being threaded. The exterior surface is thoroughly coated with zine applied directly to the metal so that galvanic protection against corrosion as achieved. The interior surface is protected by special lubricating coating to permit easier wire pulling. It can be used indoors or outdoors, and underground beneath concrate or fill. it can be used in hight voltage applications.

Newly development in galvanizing process for protection against atmospheric corrosion and exterior erosion which is finished with heavy duty galvanized protection both inside and outside the conduit pipe (Class 4 - Heavy protection both inside and outside - refer to BS 4568 : part 1 : 1970).

Features:

1. High Quality Conduit,

2. High Quality Galvanization,

3. Heavy Duty Galvanized Protection - Class 4,

4. Easy Wire Pushing and Pulling,

5. Modern Process & High Quality Material,

6. International Quality Management System,

7. International Health and Safety Management System,

8. International Product Certification,

|

|

|

| Steel Pipe Conduit |

Steel Pipe Conduit |

Steel Pipe Conduit |

|

|

|

| Steel Pipe Conduit |

Steel Pipe Conduit |

Steel Pipe Conduit |

|

|

|

| Steel Pipe Conduit |

Steel Pipe Conduit |

Steel Pipe Conduit |

RIGID STEEL CONDUIT SYSTEMS

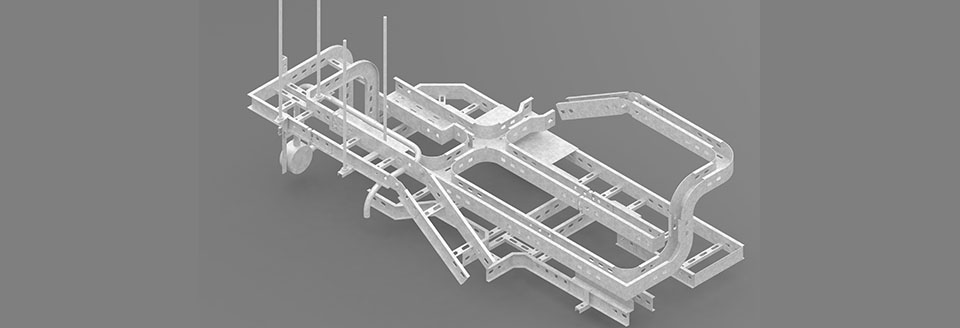

ELPRO's Rigid is precision manufactured for dependable, long lasting value and protection for the electrical raceway system.

Threads shall be hot-dipped galvanized after cutting and produced in accordance with American National Standard Institute (ANSI) C80.1

Manufactured from high-strength strip steel, ELPRO's Rigid combines damage-resistant strength with ductility to assure easy bending, cutting and joining. It also provides smooth, continuous raceways for fast wire-pulling. No need to worry about damage to the conduit system even when pulling through multiple 90 degree bends.

ELPRO's Rigid is hot-dipped zinc galvanized, then a conversion coating is applied to form an additional protection layer against corrosion and abrasion.

ELPRO's Rigid provides radiation protection and magnetic shield and resists impact.

|

|

|

| Rigid Steel Conduit |

Rigid Steel Conduit |

Rigid Steel Conduit |

|

|

|

| Rigid Steel Conduit |

Rigid Steel Conduit |

Rigid Steel Conduit |

|

|

|

| Rigid Steel Conduit |

Rigid Steel Conduit |

Rigid Steel Conduit |